Product

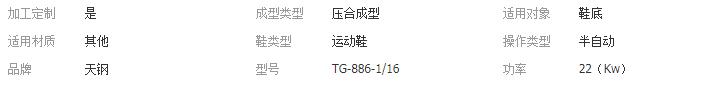

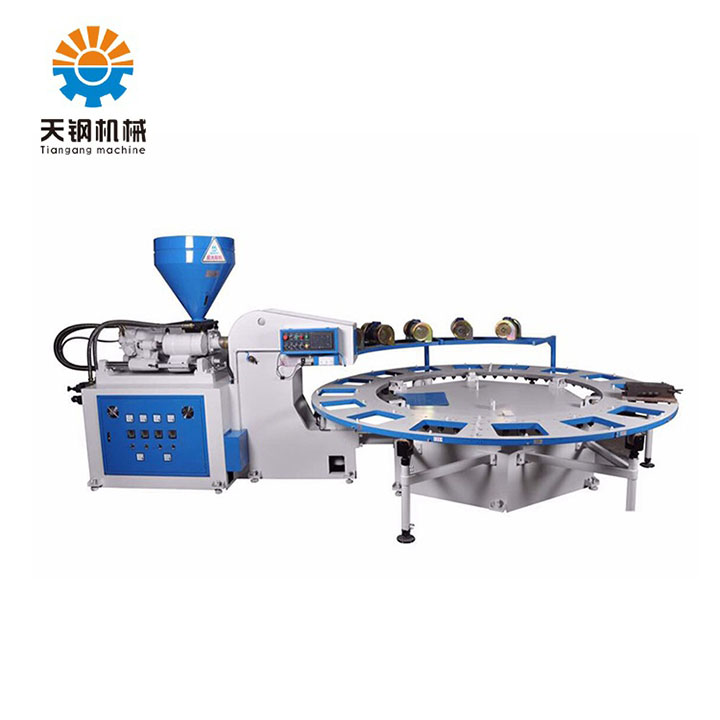

Tiangang Machinery TG-886-1 Automatic Disc Monochrome Plastic Sole Injection Mol

Product Details

Casting machine FAQ

1. Don't know what is the best pouring? This in turn leads to an erroneous evaluation and selection of the pouring device.

2 The vertical split type boxless molding line is used, but the wrong choice of refilling or low-efficiency pouring machine is required.

3 The vertical split molding line is used, but the horizontal split molding line pouring machine is mistakenly selected.

4 Non-heated pouring machine is used for horizontal classification and pouring gray iron with box molding line. This is definitely not an ideal choice, especially for the production of large and complex parts (such as engine body and cylinder head casting), which is simply a mistake.

5 It is wrong to believe that the horizontal molding line casting machine must have the function of chasing the package in order to produce normally.

6 In high-speed molding lines, it is mistaken to believe that manual casting is more economical than fully automatic casting machines.

7 ball iron production, the wrong choice of non-ball iron casting machine.

8 A large number of over- and under-fillings occur, sometimes over-plating or even damage to the molding line.

9 Confuse the difference between mechanized pouring machine, predictive semi-automatic pouring machine and fully automatic pouring machine.

10 When there is a spray, the molten iron splashes a lot.

11 Slag holes and stomata waste products are more, and sand washing is serious.

12 castings have a low yield.

13 The effect of gestation is not good, and the quality of castings is not high.

14 The temperature loss of the casting machine is too large, and the temperature drop is very large, often reaching 5-8 ° C / min.

15 plug and sprue life is too low, often leaking and cost is too high.

16 pouring machine lining life is too low.

17 The casting machine has too much oxidized slag and it is difficult to remove

PREV:Tiangang Machinery TG-PU30D-2A Polyurethane Sole Forming Production Line Press F

NEXT:Tiangang Machinery TG-LB-20x11M Automatic Semi-automatic Disc Preformed Foaming

Related

Self-produced and sold Monochrome automatic-buckle shoe machine Disc-type sole i

TG-886-3 Fully automatic disc type two-color plastic sole injection molding mach

Fully automatic semi-automatic continuous shoe sole foam injection molding machi

Off-the-shelf Two-color automatic plastic bottom injection molding machine High-